Do you hate how long it takes for your 3D printer heated bed to reach temperature? Want to save on the energy costs of your 3D printer? Add insulation to your heated bed! We have tested a few common and inexpensive materials that can be used as 3D printer heated bed insulation. Insulation not only saves you time and money but will improve the consistency of your heated bed surface.

Things to consider: Available space under the heated bed

The space under your printer will be critical for choosing a heated bed insulation material. If you have only a few millimeters, then your options will be limited to thin materials such as the cork sheet we tested. Also, watch out for the possibility of the material to get caught in the linear mechanisms or in the wiring for the heated bed.

Max temperature of the heated bed

Some materials and adhesives cannot handle the high temperatures of a heated bed. Generally, these materials can withstand up to 100°C, but proceed at your own risk and follow the manufacturer's recommended temperatures before use. If your printer fails, there is a chance that these added materials can catch or help fuel a fire.

Availability of materials

The materials we tested are very common and are found in many households. These materials are easy to find and test. Cardboard and foam can be taken from leftover packaging material, and foam core and cork can be found at a local crafts store.

Price

All of the materials we tested can insulate most heated print beds for well under $5. There are more exotic and expensive materials that hobbyists have used if you are interested in. Based on our testing, these seem to work very well for the price.

Adhesives

Some materials can come adhesive backed, such as the cork sheet. If you need to add adhesive to make it stick to the bottom of your heated bed, we recommend 3M Super 77 adhesive spray, carpet tape, or another type of double-sided adhesive tape that can withstand the temperatures you print it.

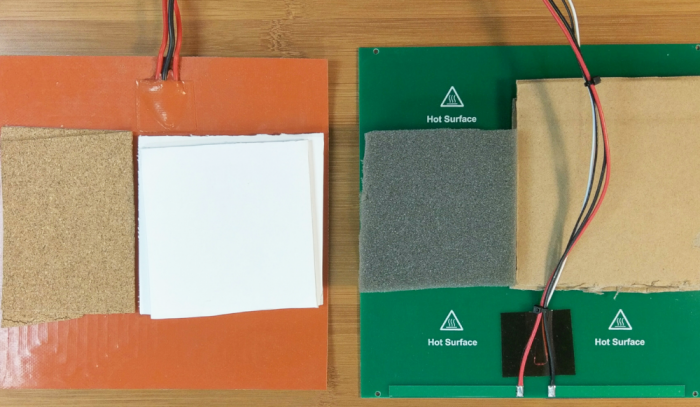

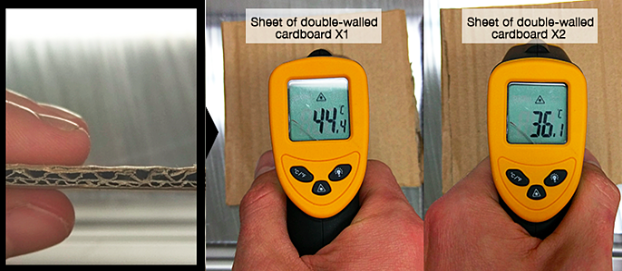

Materials We Tested: Double-walled cardboard insulation

Single sheet of double-walled cardboard experienced a 21°C drop in temperature. Adding a second sheet of double-walled cardboard experienced a 29°C drop in temperature. Single-walled cardboard would be expected to perform worse than double-walled.

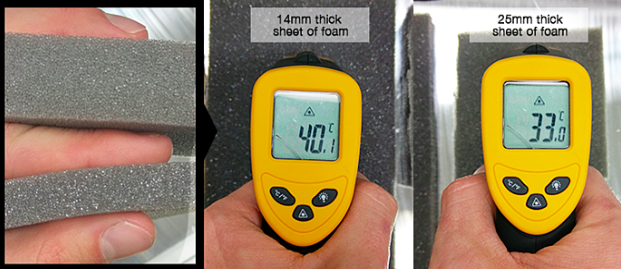

Polyurethane foam sheets

14mm thick sheet of foam experienced a 25°C drop in temperature. Using a 25mm thick sheet of foam saw a 32°C drop in temperature. This is open-cell foam which is not as effective for the same volume as closed-cell. If there is a lot of space under your heated bed then this could be a good solution.

Foam core sheet

Single sheet of 5mm foam core sheet experienced a 26°C drop in temperature. Adding a second sheet provided a 33°C drop in temperature. This closed-cell type foam performed very well in our testing and is highly recommended.

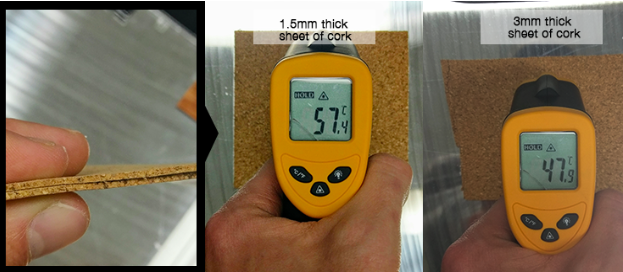

Cork sheet

The 1.5mm thick sheet of cork experienced a 8°C drop in temperature. Doubling the thickness to 3mm thick sheet saw a 17°C drop in temperature. The cork we tested was quite thin but will provide some insulation if your printer has minimal space under the heated bed.

Check out more posts about 3D printings:

- 7 Reasons Why You Should 3D Print On Glass Bed

- Effects of Temperature on PLA and PETG 3d Printing Filament

- Low Cost Dust Shoe for the X-Carve CNC Router

Want to know more about our updates? Click to read our other posts!

This article was published by OhmniLabs, a member of the Kambria Manufacturing Alliance. Please follow their blog for more technical content.