Additive manufacturing using commercially available 3D printers gives us the ability to quickly produce and iterate our designs. Since we are using these end use products, it is critical to understand the consequences of using such machines and associated materials. This week, we focused on understanding the effect temperature has on two types of common 3D printing filaments, PLA and PETG.

PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene) filaments are the most popular forms of filament. PLA is biodegradable and has a low melting point and glass transition temperature. ABS is a very durable plastic but requires higher print and heated bed temperatures than PLA. Unlike PLA, ABS is considered an engineering material. However, ABS is prone to warping and creates toxic fumes while printing.

PETG (polyethylene terephthalate glycol-modified) is becoming a more widely used filament for fused deposition modeling (FDM) machines because it is the best of both worlds. PETG has the durability of ABS without significant warping and toxic fumes. It has a higher melting and glass transition temperature than PLA, but still not quite as high as ABS.

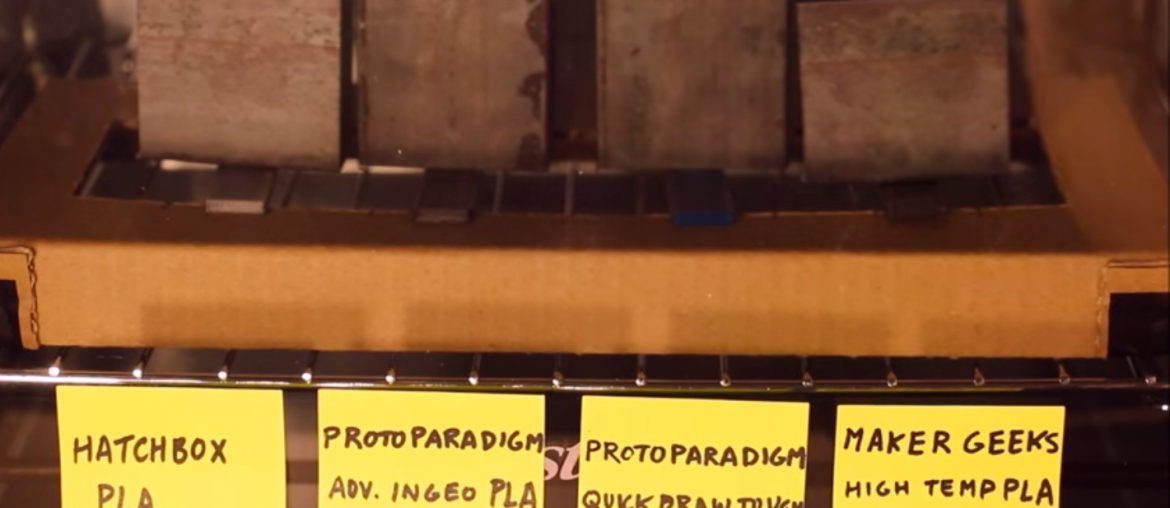

Our goal was to test the differences between the glass transition temperatures of both PLA and PETG. We tested four filaments of PLA and six filaments of PETG from various manufacturers. The test consisted of 400g weights that were applied to standard-sized specimen strips, which were heated in an oven. We slowly increased the temperature of the oven to reveal the overall difference between PLA and PETG, and the variance between different filament manufacturers.

The results indicated that the various PLA specimens softened between 55℃ and 60℃, while PETG specimens softened between 75℃ and 80℃. The approximately 20℃ temperature increase before deformation is a significant finding. Simply put, PETG can be used in more extreme temperature environments than PLA. For example, PETG is likely to survive the common example of the inside of a parked car on a hot summer’s day, while PLA may not.

Between the brands of filament we tested, there were no significant differences found of the glass transition temperature. That said, we expected the Maker Geeks PLA to deform at a much higher temperature than approximately 55℃. We used their “Raptor Series” Dishwasher Safe PLA in True Black, which is marketed on their website to withstand up to 125℃ and the “sanitizing heat of a dishwasher with no deformation”. The specimen did seem to deform less than the other filaments at the same temperature, but the specimen clearly had deformed by reaching its glass transition temperature well below the advertised 125℃.

The PETG tests showed that the Atomic Filament PETG had the lowest glass transition temperature. It is possible that this is because of the purity of their filament. Atomic Filament is known for its high-quality filament without high melt point additives, waxes, or fillers. Other manufacturers additives may increase the glass transition temperature in their filaments, for better or for worse. These additives may have other beneficial or adverse effects on the printing behavior of the filament. Atomic Filament states that their quality ensures consistent performance, so a slightly lower glass transition temperature may only be a small factor in the usability of the filament. ESUN PETG and Maker Geeks PETG filaments were the last to deform, at just over 80℃.

This article about 3D printing filaments was published by OhmniLabs, a member of the Kambria Manufacturing Alliance. Please follow their Blog for more technical content.